Autoclave Sterilization Cycle or Autoclaving Process

- Autoclave Sterilization Cycle : The autoclave is frequently used to sterilize various pieces of equipment and media in practical labs, businesses, and healthcare facilities.

- Items are placed within an autoclave chamber under controlled temperature, pressure, and steam conditions for a predetermined amount of time, either wrapped or placed directly over the holding plate.

- An autoclave functions basically similarly to a pressure cooker, which we frequently use to boil or cook food.

- It could close the door or lid of an autoclave to create a sealed chamber similar to one in a pressure cooker.

- Afterward, depending on the type of autoclave, air displacement systems like steam, steam flushes, and vacuum systems remove the air from the pressure vessel.

- After then, by raising the autoclave’s temperature and killing power- ability, the pressure inside the device enables successful sterilization at the specified time.

- After the media and equipment have been sterilized, release the steam.

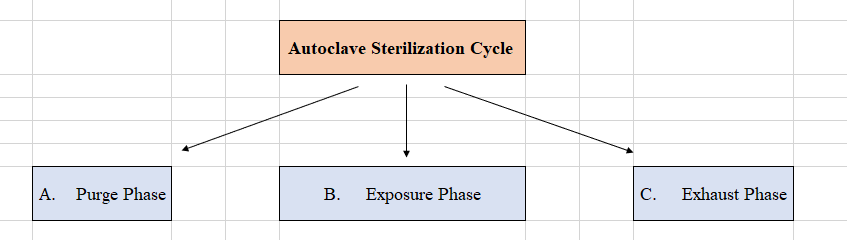

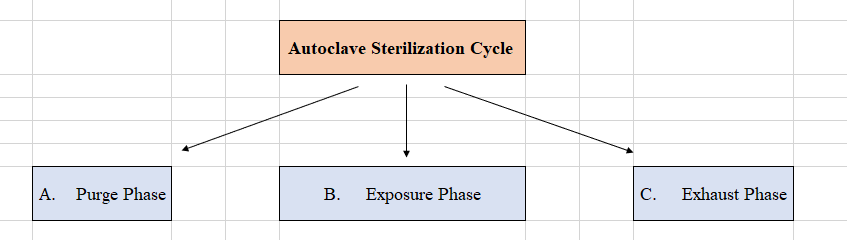

- There are three stages or Phases in the autoclave sterilization cycle as a result, depending on how an autoclave operates:

- Purge Phase

- Exposure Phase

- Exhaust Phase

Autoclave Sterilization Cycle Process:

A. Purge Phase (Conditioning Phase):

- Additionally, it describes the as “Conditioning Phase”, which entails or required for displacing or removing air from the pressure vessel that can obstruct the sterilization procedure.

- To remove air from the chamber, different autoclaves employ various techniques.

- Steam is used to displace the air in a “Gravity Displacement Autoclave”.

- It employs pressure pulses and steam flushes for its “Positive Pressure Displacement Autoclave”.

- Negative pressure (vacuum) displacement type, in which all the air is removed using a vacuum pump.

B. Exposure Phase or Sterilization Phase :

- In order to continuously deliver steam into the pressure vessel through a heating element during the sterilizing phase, it must be closed the autoclave’s exhaust valve.

- It causes the temperature and pressure to quickly rise to the appropriate setpoint.

- Then, depending on the kind and load of the content, the chamber’s contents undergo the exposure phase under sterilization temperature exposure for the necessary amount of time.

C. Exhaust Phase:

- The final phase includes the release of an exhaust valve to release steam out of the autoclave chamber or depressurize it.

- As the steam entirely evaporates, and take out the sterilized material.

Read More:

- Type of HPLC Detectors

- Difference between HPLC and UPLC

- Data integrity

- Controlled Drug Delivery System

- Data integrity

- Controlled Drug Delivery System

- GAMP Guideline

- Acronyms and Abbreviations

- Alcohol Dose Dumping

- Autoclave Sterilization Process Guide – Tuttnauer

- Autoclave Machine: Uses, Guidelines & Cost – STERIS

- Documentation Practice (GDP) & ALCOA++

- Female Infertility

- Inflammatory Bowel Disease (IBD)

- In-Vitro-Fertilization (IVF)

- Tablet Friability